- About

- Guitars

- Mandolins

- Ukuleles

- Dulcimers

- Mandola

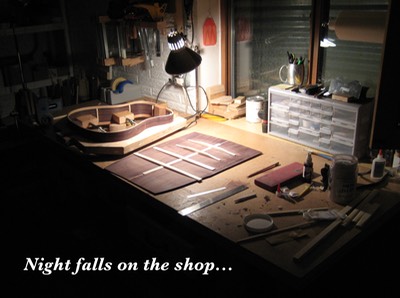

- Dale's Blog

- Photos

- Jam Session at Brian's

- Parlor Guitar Build Photos

- Tenor Ukulele

- 00 Concert Guitar Build Photos

- A back brace ready to be sanded for the back's 15’ radius

- A back brace sanded to 15’ radius conture. Radiusing improves structure and tone.

- Top and Back Braces are fashioned from Sitka spruce blocks.

- Using the Safe-T-Planer to begin thickness process

- Sanding off scratches from drum sander

- Back plate halves ready for gluing

- Gluing back plate halves together

- Back ready for bracing

- Using the Go-Bar deck to glue the back braces

- Tapering the back braces

- Completed back

- Top plate halves glued together

- Resizing dreadnought rosette for Concert guitar

- Routing for the rosette and purfling rings

- Routed and ready for gluing

- After gluing, a cabinet scraper is used for leveling

- Leveled and sanded

- Putting a radius on the tail block. Sand until pencil marks are gone.

- Ready for sealing

- Tail block and heel block sealed and ready to receive the sides

- X-braces joined and glued to the top.

- The X-brace joint reinforcement

- Top braces and bridge plate in place

- Top tuned, braces shaped and sanded

- Sides thicknessed and ready for bending

- Bending a side

- After bending, the sides are placed in the body mold

- Planing the sides to near final height

- A 15’ radius sanding disc is used to radius the rim set

- Radiusing involes a lot of planing and sanding

- Sanding is done by rotating the form like a steering wheel

- Sawdust and shavings

- Kerfing provides glue contact areas for top and back

- Chalk is used to know when to stop sanding the kerfing

- Radiused rim set

- Using a cutting guide to cut end wedge slots

- Gluing the end wedge in place

- The end wedge

- Gluing the back to the sides

- Inside before gluing on the top

- Gluing the top to the sides

- Gluing the neck scarf joint

- Routing the binding channels

- Router set-up

- Process for gluing bindings

- Top bindings glued and bound

- Scraping the Bloodwood bindings

- Some naptha on the koa to see how it will look

- A bit like Birdseye Maple! Nice.

- The completed body.

- A neck blank and a neck in progress

- A Scarf Joint creates the headstock angle

- Carbon fiber is used for neck reinforcement

- Using the Neck Jig to rout the mortise slot

- A closer look at routing the mortise slot

- Routing the neck tenon

- Neck adjust to fit body

- Heel ready for mounting inserts

- Installing the neck mount inserts

- Cutting fret slots

- Installing the Koa heel cap

- Gluing the laminated headplate

- Thicknessing the headstock

- Beginning to carve the neck

- Would you like curly fries with that?

- Working on the middle

- …and the heel

- Carved neck and shavings

- Putting a 16’ radius on the fretboard

- Macabauba fretboard with marker dots

- Pins to locate, bands to secure it

- Beveling the fret edges

- Preparing headplate for inlay

- Completed inlay

- Pre-finish side view

- Pre-finish back view

- Pre-finish top view

- Site Map

PIRIE Fine Instruments

Hand-crafted Guitars - Mandolins - Ukuleles - Dulcimers

Sidebar[Skip]

© Dale Pirie 2019